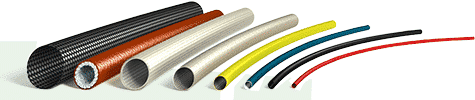

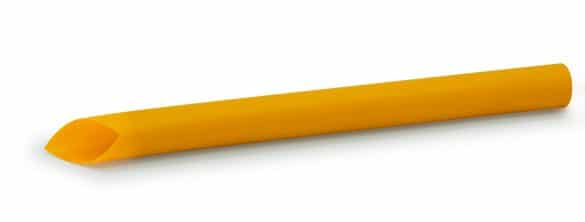

Extruded sleeving for mechanical protection

In most situations, FAVIER Group’s sleeving is used under extreme environmental or temperature conditions. On top of these comes mechanical stress which can damage this protective or insulating sleeving, reducing their technical capabilities and their thermal and electrical protection.

In order to guarantee the best possible protection to heat and electricity, FAVIER Group has developed extruded sleeving which can stand up to any type of mechanical attack, including abrasion, friction and vibrations. This means it will maintain the original thermal and electrical properties required of it.

Whether it’s made from PVC (references PVC70°, PVC105°, PVC105°UL, PVC125), polyurethane (reference Tubothane®), EPDM (reference GETC), polyolefin (reference GTR and TER) or silicon (reference GES and SIL), FAVIER Group’s sleeving will meet all of the strictest international standards.

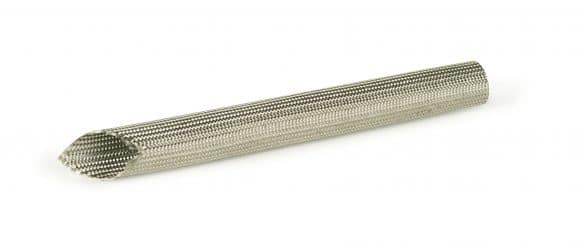

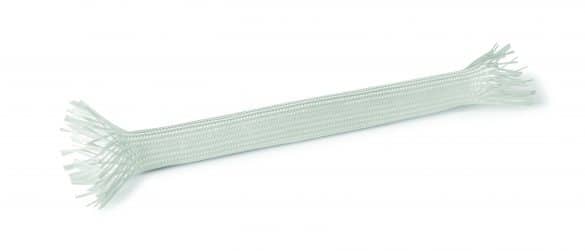

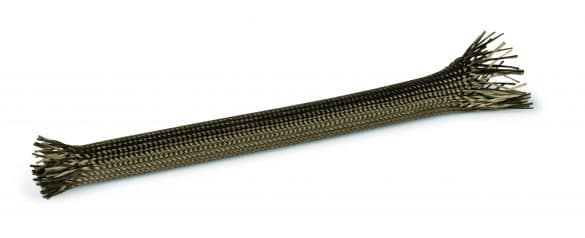

Textile sleeving for mechanical protection

In addition to our extruded sleeving, FAVIER Group has also integrated a full range of textile sleeving for mechanical protection. This offers greater suppleness and flexibility than extruded sleeving. This textile sleeving is primarily used to protect cables, cable bundles and flexible hydraulic tubing for the automobile, electro-mechanical, electrical appliance, steel and rail sectors.

The main materials used are plastics, such as monofilament polyester (GPB reference) and polyamide (reference NPS). This sleeving provides protection to cables or flexible tubing from abrasion or cuts, and will also help increase the lifetime of your protected cables and tubing. Moreover, in certain cases it will help protect operators in the event that a hose bursts.