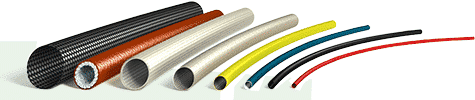

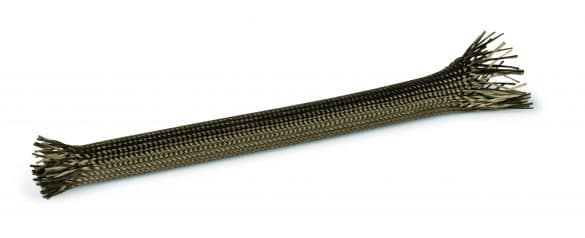

Braided electrical protection sleeving

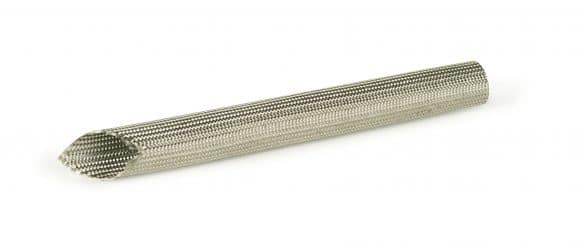

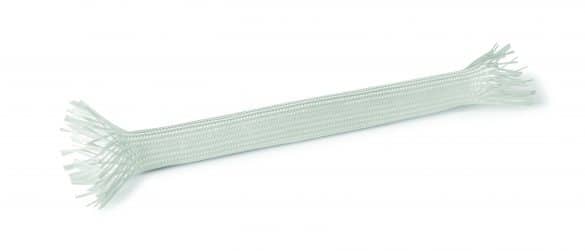

The electrical insulation sleeving manufactured by FAVIER Group consists of finely braided fibreglass and various coatings, depending on the temperature ranges defined by the target application for the sleeving.

The production process is the result of many long years of skill, expertise and experience, allowing us to guarantee the best possible performance in terms of electrical protection. This also allows us to offer extremely flexible and extensible sleeving which is both hermetic and adapts to the required diameter.

This braided insulated sleeving can be used for voltages ranging from 1.5kV to 20kV and under temperatures from -60°C to +250°C with peaks of up to +290°C.

What’s more, this electrical protection sleeving meets the most stringent standards: our sleeving is UL-approved (UZIQ2, UZFT2, UZKX2), they meet the requirements of the NF EN 60684 standard relating to “testing methods for flexible insulating sheaths, including thermo-retractable sleeving, initially designed to insulate electrical conductors and connections for electrical devices, even if they may be used for other uses”.

The various FAVIER Group electrical insulation sleeving products (the SCS, 15C, SCS-E, PVC, SVF, 13F3, 13F3AC, SEP, SEP-R, SEPx2) provide optimal electrical insulation while guaranteeing good resistance to soldering irons, to impregnating varnishes and to UV. What’s more, they are halogen-free and hermetic.

This braided sleeving is used in sectors with the strictest quality requirements, such as automobile, aeronautics, rail, electro-mechanics (electric motors, transformers, alternators and generators), electrical appliances and lighting.

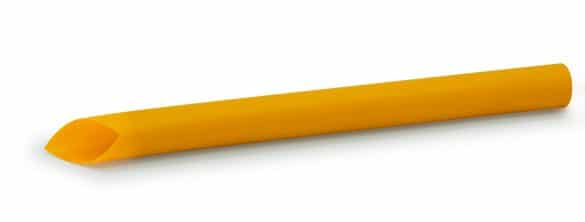

Over the years, FAVIER Group has diversified and now manufactures extruded sleeving to guarantee flawless electrical insulation. This extruded electrical protection sleeving consists of materials such as PVC (references PVC70°, PVC105°, PVC105°UL, PVC125), polyurethane (reference Tubothane®), EPDM (reference GETC), polyolefin (references GTR and TER) and silicon (references GES and SIL).

Just like our braided fibreglass sleeving, our extruded electrical protection sleeving meets all major standards and requirements:

- Compliant with the RoHS 2011/65/EU directive

- NF EN 60684

- UL224

- UL94 (PVC105°), file E345725/li>

Our extruded sleeving is hermetic, extremely flexible and guarantees electrical protection from 10kV/mm to 20kV/mm.

This extruded electrical sleeving is used in sectors with the strictest quality requirements, such as automobile, aeronautics, rail, electro-mechanics (electric motors, transformers, alternators and generators), electrical appliances and lighting.